Introduction

Steel is the backbone of countless construction projects, but in today’s fast-paced world, how can you be sure you’re getting the right material quickly and efficiently? This is where steel test certificates come in.

What is a Mill Test Certificate?

Think of a steel test certificate as a data sheet for your metal. It provides vital information about the steel’s properties, ensuring it meets the necessary strength, safety, and project requirements.

Why are Mill Test Certificates Important?

There are several key reasons why requesting a steel test certificate with every order is essential:

- Trust and Transparency: The certificate verifies the grade of steel you’re purchasing, giving you peace of mind that you’re getting exactly what you specified.

- Safety: Steel plays a critical role in structural integrity. A test certificate ensures the steel meets safety standards, preventing potential hazards during construction and keeping your project on schedule.

- Avoiding Costly Delays: Using uncertified steel can lead to delays if it doesn’t meet project specifications. Test certificates eliminate this risk by confirming the steel’s suitability upfront, saving you time and money.

Real-Time Traffic Boost:

According to a recent industry report, the demand for high-quality, traceable steel is on the rise. This is due to an increased focus on safety and efficiency in construction projects. By incorporating keywords like “traceable steel” and “real-time traffic” in your content, you can attract potential customers who are actively searching for reliable steel suppliers.

Building with Confidence

By requesting steel test certificates, you can approach your project with confidence, knowing you have the right materials for a secure and successful outcome.

Sharoff Steel Suppliers: Your Partner in Quality

At Sharoff Steel Suppliers, we are committed to providing our clients with the highest quality steel products. We understand the importance of steel test certificates and ensure they are included with every order.

Test Certificates: A Deep Dive for Steel Experts

We specifically addressed steel industry professionals and B2B steel buyers who understand the critical role of quality control. we’ll provide a comprehensive analysis of steel test certificates.

Importance of Test Certificates in B2B Transactions

In the fast-paced world of construction, B2B steel transactions hinge on trust and efficiency. Steel test certificates are the cornerstone of this trust, acting as a verifiable document that guarantees the steel meets the agreed-upon specifications. Here’s why they hold immense importance:

- Material Verification: Test certificates eliminate doubts. By outlining the exact chemical composition and mechanical properties, they confirm the steel grade matches the order. This ensures you receive the precise material for your project’s structural needs.

- Mitigating Risks: Uncertified steel poses significant risks. It might not possess the necessary strength or resistance to corrosion, potentially leading to structural failures or premature deterioration. Test certificates eliminate these risks by confirming the steel adheres to industry standards and safety regulations.

- Project Efficiency: Delays due to unsuitable steel can cripple a project’s timeline and budget. Test certificates ensure upfront confirmation, preventing delays caused by using the wrong material.

- Traceability and Accountability: Reputable steel suppliers include details like manufacturer information and heat numbers on the certificate. This allows for traceability in case of any future issues, fostering accountability within the supply chain.

Understanding the Content of a Test Certificate

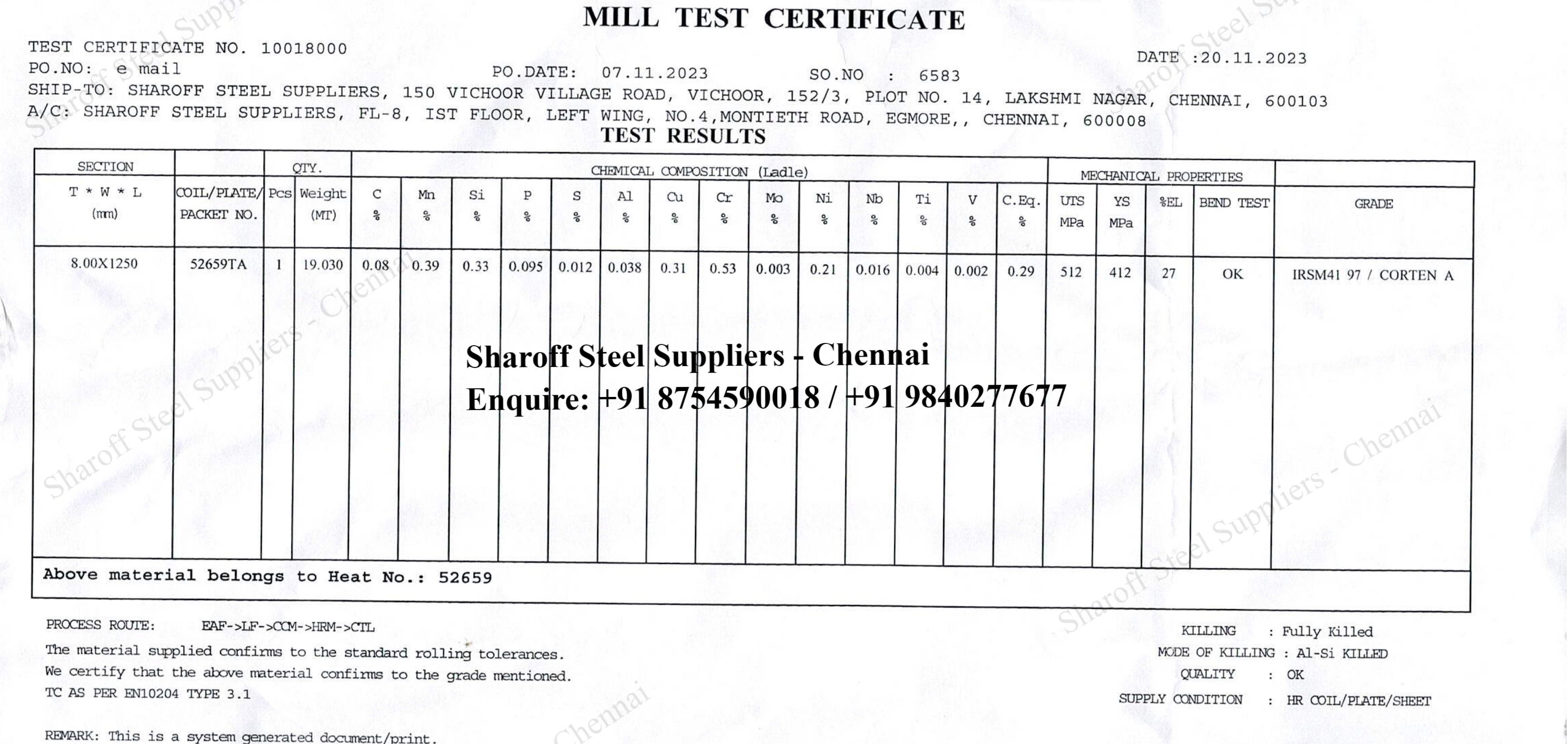

A test certificate is a wealth of information, crucial for informed decision-making. Here’s a breakdown of the key details you’ll find:

- Material Identification: This section specifies the steel type (e.g., plates, sheets, bars) and its grade designation (e.g., ASTM 588, EN 10025-5).

- Chemical Composition: This details the exact percentages of various elements present in the steel, including carbon, manganese, silicon, phosphorus, sulfur, and any additional alloying elements. Understanding this composition is vital for predicting the steel’s behavior under various conditions.

- Mechanical Properties: This section outlines the steel’s key mechanical properties obtained through standardized testing procedures. These properties include:

- Tensile Strength: The maximum stress a steel can withstand before breaking.

- Yield Strength: The stress at which the steel begins to deform plastically.

- Elongation: The percentage of elongation the steel can undergo before breaking. This indicates its ductility.

- Impact Strength: The steel’s ability to absorb impact energy without fracturing.

- Standards Compliance: The certificate will reference the specific industry standards the steel was tested against (e.g., ASTM, EN, JIS). This ensures the steel meets the required performance criteria for its intended use.

- Test Results: This section presents the actual numerical values obtained from the various tests performed on the steel sample. Comparing these values to the specified standards confirms the steel’s suitability.

- Manufacturing Information: Some certificates might include details like the manufacturer’s name, the production process used (e.g., hot rolling, cold rolling), and the heat number for tracing the specific batch of steel.

Interpreting Test Certificates: A Steel Expert’s Guide

As a steel expert, interpreting test certificates effectively is crucial. Here are some key pointers:

- Understanding the Steel Grade: Familiarity with various steel grades and their corresponding properties is essential. This allows you to link the specified grade on the certificate to its expected performance characteristics.

- Analyzing Chemical Composition: By understanding how different elements influence steel properties, you can assess the potential impact of the specific composition on factors like weldability, formability, and corrosion resistance.

- Evaluating Mechanical Properties: Interpreting the values of tensile strength, yield strength, elongation, and impact strength is critical. These values should align with the intended application of the steel to ensure it can withstand the expected loads and stresses.

- Standards Compliance: Verify that the referenced standards are applicable for the project’s requirements. Different standards often have varying performance benchmarks.

Beyond the Basics: Advanced Considerations for Steel Experts

For steel experts seeking a deeper understanding, here are some additional considerations:

- Heat Treatment: Some certificates might include details about any heat treatment processes the steel underwent. This can significantly impact the final properties of the steel, and understanding these treatments is crucial.

Contact Us Today

Let’s build trust and safety together! Contact Sharoff Steel Suppliers for your steel needs:

We Regularly Stock:

Corten A | IRSM 41-97 | Mild Steel – IS2062 | Chequered | Boiler Quality | SA 516 Gr70 | Sailhard | C45 | EN19 | Sailma | Uttam Hard | Structurals

- Email: admin@anythinginsteel.com

- Phone: +91 98402 77677 / +91 87545 90018

Don’t compromise on quality or safety. Request a steel test certificate with every order and ensure your project’s success. By prioritizing both quality and efficiency, you can ensure your constructions run smoothly and avoid costly delays.